French design

From Paris to Fukui

At the very beginning, during the drawing stage, we like to retreat to the city of Fukui, nestled between the mountains and the Sea of Japan, close to our factory.

We bring with us notebooks filled with sketches of shapes, colors, and impressions from our time between Paris and Tokyo.

In this calm place, where the spirit of the pioneering artisans of Japanese eyewear still lives, our new creations take shape.

Japanese quality

"Japanese craftsmanship subjected to the most rigorous quality control"

In the city of Sabaé, three hours from Tokyo on the shores of the Sea of Japan, eyewear manufacturing has earned the most prestigious reputation since the early 20th century, from handmade prototypes to assembly, polishing, and quality control.

各プロトタイプは、量産に入る前に技術図面の精度とデザインの実現性を確かめるため、すべて手作業で仕上げられる。

「ANNA」モデルのアセテート表面は、すべて職人の手で磨き上げられる。

コットンホイールと専用の研磨ペーストを用い、下地の荒削りから滑らかに整える工程を経る。

仕上げの鏡面磨きでは段階ごとに最適なペーストを使い分け、光沢のある美しい表面を生み出す。

製造の最終工程では、すべてのフレーム(ここではANNAモデル)が厳格な品質検査を受け、高い基準を満たしたものだけが完成品となる。

It is also in Sabaé, at the company Tega Seiko, that the metal components forming the frame structure and hinges of our glasses are produced. When it comes to assessing the durability of a frame, the hinges play a central role.

Innovation

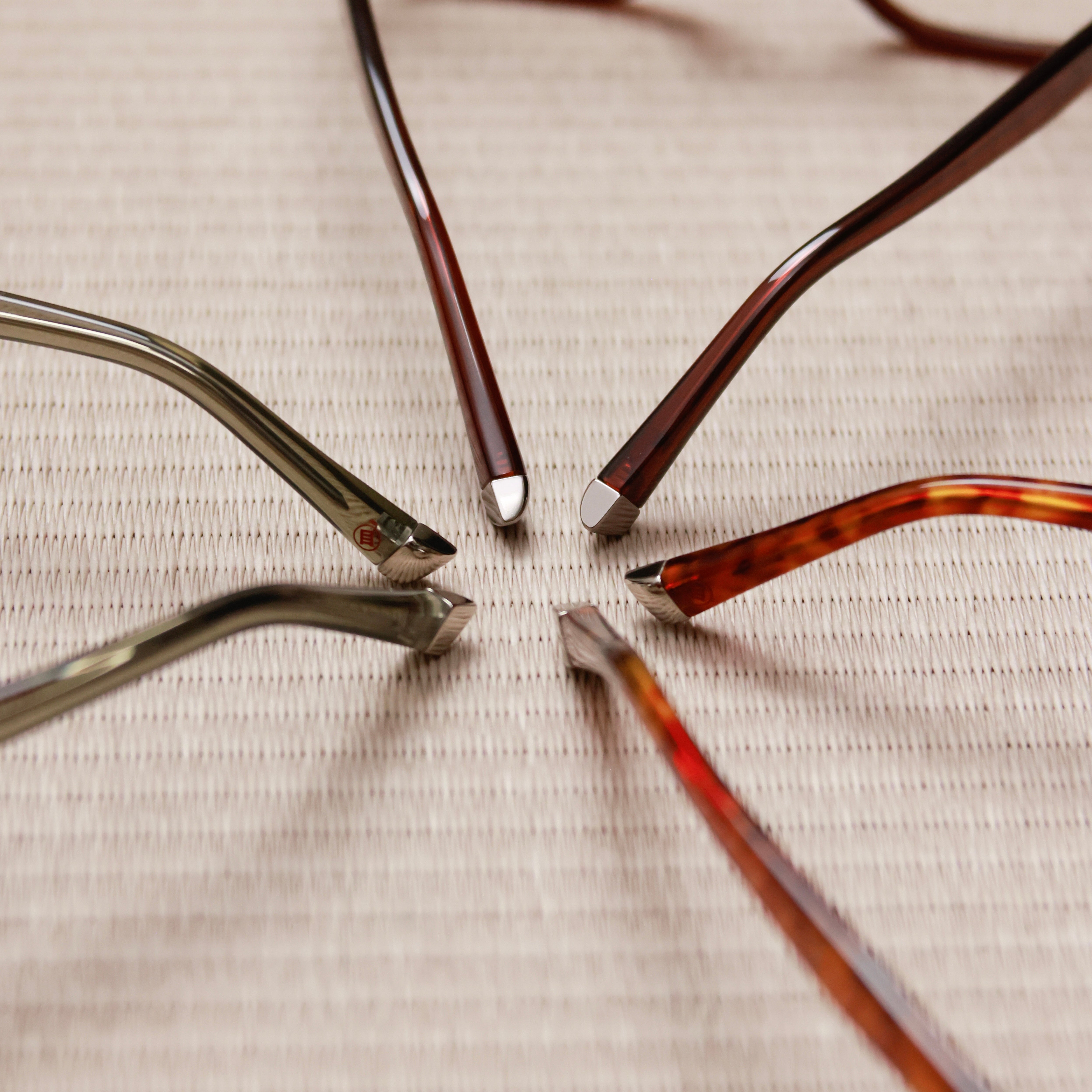

Titanium temples’ tips

The titanium tips, inserted at the end of the temples (THEO and ANNA models), add a slight weight (1,58 grams) to shift the center of gravity backward. Instead of being located at the front of the frame, near the hinge as is usually the case, it is now positioned roughly at the first third of the temple, providing a feeling of lightness at the front for optimal comfort.